How job costing works in Ontraccr

New to job costing?

If you'd like to learn more about what job costing is and how to implement modern techniques, you can refer to the following resource:

Why your construction company should start job costing

Job costing gives you a complete picture of all costs associated with a specific project and allows you to categorize them via cost codes. Ontraccr makes it easy to implement your own job costing system quickly.

Setting up cost codes

To start job costing, the first thing you need to do is set up your list of cost codes. Cost codes are unique to each trade/industry but they typically represent specific tasks being done on a project. For example, for a general contractor, cost codes would be used for activities such as excavation, foundation, framing, drywall, painting, and so on.

Cost code types

There are two types of cost codes in Ontraccr:

Global cost codes serve as a quick template for all future projects that are created within Ontraccr and can be easily imported during a project's initial creation. You can think of this as your company's master list of cost codes, which are commonly used across your projects. The purpose of global cost codes is to standardize your company's job costing metrics and to also save time when setting up your job costing system for each project by avoiding double entry.

Project-specific codes are cost codes that are associated to a specific project. Project-specific cost codes can either be added directly to the project or they can be imported from your global cost codes.

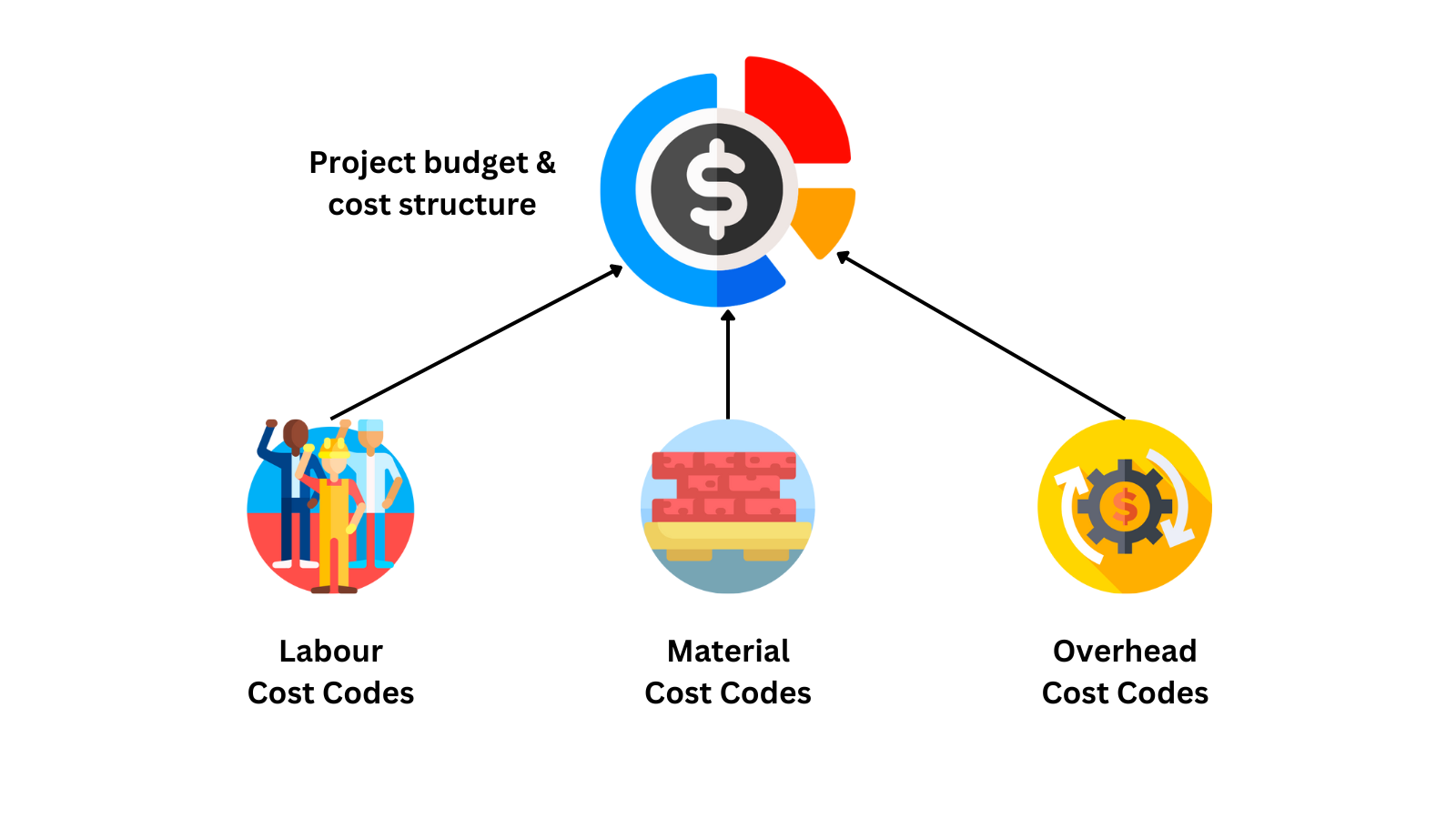

Cost code categories

In OnTraccr, there are three main cost code categories: Labour, Material, and Overhead.

Labour cost codes represent both the direct and indirect labour aspects of your job. Direct labour represents the hours that are directly required to complete the project, whereas Indirect labour represents the hours that are required to support the production process, such as supervision or planning.

Material cost codes can also be broken down into direct and indirect costs. Direct material costs would be material that is being installed in the project as part of the finished product. Indirect material costs represent things like the rental of machinery or tools required to aid in the construction of the finished product.

Overhead cost codes represent all the remaining costs on the project above and beyond just labour and materials. For example, you may require a project manager to manage the project, or perhaps you have to pay rent for your office/warehouse.

Setting the project budget & tracking costs

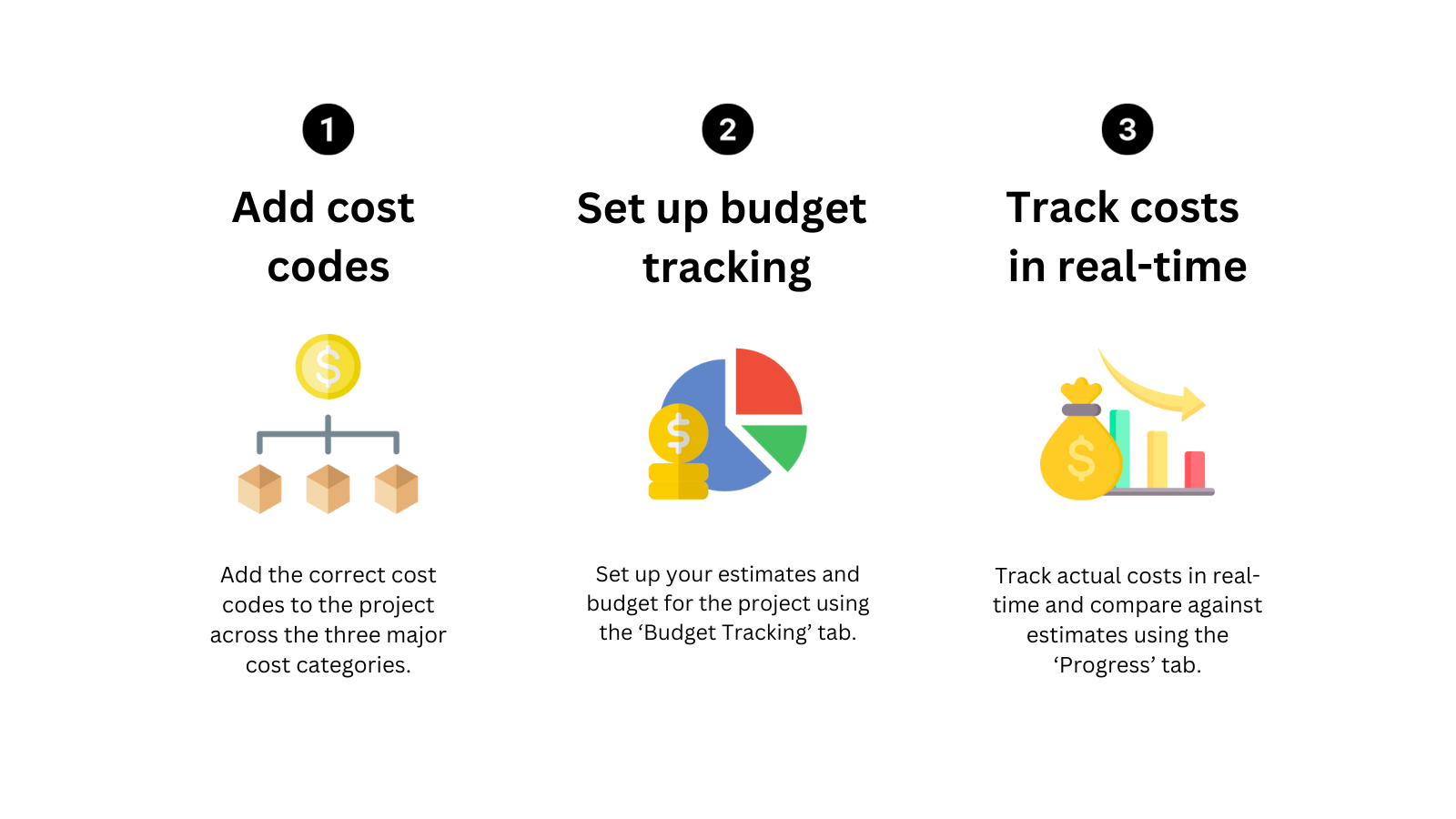

When you’re ready, you can set up the entire operational budget for your project with the easy-to-use 'Budget Tracking' tab in the project profile. You can set this up either when first creating the project profile or you can always go back and add the budget tracking system into your project after it's been added into Ontraccr.

When setting your project budget, add your cost estimates across the major cost code categories and Ontraccr will track your actuals automatically. For projects that have many phases such as a multi-story building, you can even further break down your estimates across the various phases of your project and ensure that costs line up the way you expect them to.

After the project's budget tracking system has been set up (including the full set of cost codes for the project), you can use the 'Progress' tab in the project profile to track the project's actual costs in real-time and see how the actuals are trending against the original estimates.